The Ultimate Guide To American Plastics

5 Simple Techniques For American Plastics

Table of ContentsWhat Does American Plastics Mean?American Plastics Can Be Fun For AnyoneIndicators on American Plastics You Need To Know5 Simple Techniques For American PlasticsEverything about American Plastics

A little research can assist you with time. It is hard to judge its high quality in the beginning glimpse with the appearance of HDPE pipe fitting, numerous issues are exposed when utilizing, so we can only have an appropriate judgment after use. Consequently, it is necessary to pick HDPE pipeline fittings made by a specialist supplier with a great credibility and credibility.

A technical expert is essential for a good item, especially in the production industry, because a little blunder will certainly result in the failure of the entire job. HDPE pipelines can replace concrete pipelines in field systems to save time and expense of fixing broken or burst pipes. HDPE pipe is likewise a less expensive alternative contrasted to other piping materials in terms of operating and installation expenses.

American Plastics Can Be Fun For Anyone

HDPE pipelines are made with solid straight or curved areas. It is made from lightweight products that are very easy to deliver and does not call for heavy installation equipment such as hefty cranes. The mix of lightweight and flexible structures makes it perfect for earthquake-prone areas. The pipelines are not breakable and can be easily put right into a rounded area without extra jointing or welding.

Chemicals resistant to HDPE pipelines can infect the pipe. The pipe does not function with chemicals and does not melt warmth or power.

HDPE pipelines are naturally solid and immune to damage created by exterior loads, high stress or resonance - https://freeseolink.org/American-Plastics_386503.html. The pipes can endure handling and bend even in winter. Safe eyeliner HDPE inner tubes Smooth Line Pipe Gliding lining using roller mixes Pipeline surge Plastic plumbing systems Construction of new pipes Rust resistance, no leaking, high sturdiness

Warm combination, while its challenges exist, can produce strong and trustworthy joints. Responses: The toughness and durability of HDPE can be gauged by its capacity to endure temperature levels of around 248F in the short term or perhaps a constant 230F. If your application consists of gas and fluid to access and elevate those temperature levels, HPDE piping is a dependable remedy.

Not known Facts About American Plastics

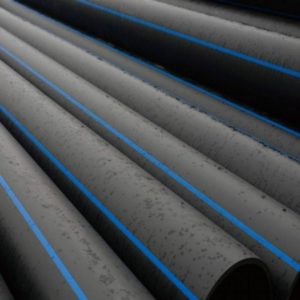

A drinkable water line/potable water pipeline is constantly dark with blue stripes and pipes passing via fluids, fluids under pressure, and process gases are constantly filled up with a yellow or black coat with yellow lines. HDPE pipe product have been utilized in the basic sector for over 50 years and their outcomes are astounding, building self-confidence amongst manufacturers that they are more concentrated on HDPE pipeline remedies.

Times considering that 1991 Removal of material requirements with scale and adjustment. In the anxiety crack resistance test the cell division demands were compromised. For that reason, it is reasonable in conclusion that HDPE pipe constructed today may have.

Each dimension classification is developed bearing in mind the demands of pressure, circulation rate, and ecological elements of the intended application. By matching the correct HDPE pipe dimension to its usage, designers and service providers can maximize efficiency and expand the life these details expectancy of their piping systems. Measurement and size are related principles in the context of HDPE pipelines.

The 3-Minute Rule for American Plastics

As mentioned previously, pipelines with reduced SDR values have the ability to hold up against higher pressures, which is an important factor to consider in the option process for tasks that involve high pressure or crucial applications. Texas hdpe pipe manufacturer. Selecting a pipe with an inappropriate SDR might result in system failing, safety risks, and costly repairs. Selecting the correct HDPE pipe dimension is critical for the success and performance of any type of piping system

Application Specifics: Tailor your pipeline size option to the specific demands of its application, whether for metropolitan, industrial, or other uses. Comprehending how the HDPE pipeline will be made use of, the awaited circulation rates and the pressure demands are critical. For circumstances, high-pressure applications may need a pipeline with a greater wall surface thickness to stand up to the interior stress and anxieties, while a lower-pressure, high-flow system might focus on diameter size to decrease rubbing loss.

The 7-Second Trick For American Plastics

Comply with these actions: Assess the Application: Figure out the pipe's planned use, consisting of environmental aspects and service conditions. Determine Flow Prices: Use industry-standard computations or software application to estimate the top and standard flow prices. Understand Pressure Needs: Determine the pressure ranking needed based upon system needs. Refer to SDR: Examine the basic dimension proportion to discover a pipe that can deal with the needed stress.

Selecting the ideal HDPE pipe dimension is a fragile equilibrium in between many technological specs and practical needs - https://free-weblink.com/American-Plastics_254084.html. With careful factor to consider and accurate estimations, you can ensure the dimension of the pipeline you choose will offer your requirements properly and effectively. Choosing the proper HDPE pipe dimension is crucial for system efficiency, longevity, and cost-effectiveness

Recognizing these aspects will certainly make certain optimal performance and compatibility throughout your piping system - Texas hdpe pipe manufacturer. The anticipated circulation price or quantity of the liquid being delivered is one of the key determinants in pipeline dimension choice. A pipeline that is too tiny can limit flow, triggering pressure loss and prospective clogs, while an overly big pipeline might cause unneeded cost and decreased system efficiency